Setting the Standard in Gas Analysis: Why Reference Methods Matter

In the rigorous domains of emissions monitoring, industrial process control, and advanced atmospheric research, the precision and reliability of gas analysis instrumentation are not merely advantageous; they are foundational to regulatory compliance, environmental stewardship, and scientific advancement. The designation of a gas analyser as a “reference standard” signifies its adherence to the most stringent metrological criteria, ensuring data integrity and comparability across diverse applications and jurisdictions.

The Metrological Imperatives of Reference Standard Analysers

An analyser earns the distinction of “reference standard” by demonstrating exceptional performance across several critical parameters, each underpinned by fundamental principles of analytical chemistry and metrology:

Stability and Repeatability

Reference analysers are engineered for long-term operational stability, exhibiting minimal deviation in response over extended periods. This inherent robustness ensures that measurements are consistently reproducible under identical conditions, a cornerstone of reliable data. The design incorporates advanced thermal management, vibration isolation, and robust component selection to mitigate environmental influences that could compromise analytical integrity.

Traceability to International Standards

Central to the concept of a reference standard is metrological traceability. All measurements generated by such an instrument must be demonstrably linked, through an unbroken chain of calibrations, to national or international primary standards (e.g., those maintained by NIST, NPL, or equivalent national metrology institutes). This ensures that reported concentrations are universally comparable and verifiable, facilitating inter-laboratory comparisons and regulatory audits. Calibration protocols typically involve certified reference materials (CRMs) with documented uncertainties, ensuring the accuracy of the calibration curve across the instrument’s operational range.

Minimal Drift and Interference

Reference analysers are characterised by exceptionally low zero and span drift, meaning their baseline and sensitivity remain stable over time, reducing the frequency of recalibration. Furthermore, their design actively minimises interference from co-existing gas species (e.g., H₂O, O₂, CO₂) that could otherwise lead to erroneous readings. This is often achieved through sophisticated optical filtering, advanced detector technologies, or integrated sample conditioning systems that selectively remove interferents without compromising the target analyte.

High Accuracy and Linearity Across Dynamic Ranges

These instruments must maintain superior accuracy and linearity across a broad spectrum of concentrations, from trace-level parts per million (ppm) to high percentage ranges. This necessitates detectors with wide dynamic ranges and signal processing algorithms that ensure a proportional response across the entire measurement scale. The uncertainty associated with measurements from a reference analyser is rigorously quantified and typically falls within exceptionally tight tolerances, reflecting its high precision.

Regulatory Recognition and Compliance

Reference standard analysers are frequently specified or explicitly referenced in international and national regulatory frameworks and testing methodologies. Examples include European Norms (EN standards like EN 14181, EN 14211, EN 12619), MCERTS (Monitoring Certification Scheme) in the UK, US EPA (Environmental Protection Agency) methods (e.g., Method 7E), and various ISO (International Organisation for Standardisation) protocols. Compliance with these standards is a prerequisite for accredited testing and certification.

Standard Reference Methods (SRMs) in Gas Analysis

Standard Reference Methods (SRMs) for gas analysis are prescribed methodologies used by regulatory bodies and industry to ensure consistent, traceable, and comparable results across instruments and laboratories. These methods are particularly important for environmental monitoring, emissions compliance (e.g., under the EU Industrial Emissions Directive or US EPA regulations), and for type approval or calibration of Continuous Emission Monitoring Systems (CEMS).

Here’s a breakdown of SRM measurement technologies commonly accepted in the UK, EU, and globally for key gaseous pollutants:

Volatile Organic Compounds (VOCs)

- Standard Method: Flame Ionisation Detection (FID)

- Reference Standards: EN 12619 (EU), US EPA Method 25A (Total Hydrocarbons), Method 18 (for speciation with Gas Chromatography)

- Measurement Type: Total Volatile Organic Compounds (TVOC)

- Advantages: High sensitivity, wide dynamic range, robust for various organic compounds.

- Applications: Stack emissions, solvent monitoring, incineration processes, petrochemical industry, both in CEMS and portable applications.

Nitric Oxide and Nitrogen Dioxide (NO + NO₂ = NOx)

- Standard Method: Chemiluminescence (CLD/CL)

- Reference Standards: EN 14792 (EU), US EPA Method 7E

- Measurement Type: NO, with a thermal or catalytic converter to measure NO₂ and report total NOx.

- Advantages: High sensitivity, fast response, widely adopted as the SRM for NOx due to its direct and interference-free measurement principle.

- Applications: CEMS, vehicle emissions testing, combustion research.

Carbon Monoxide (CO)

- Standard Method: Non-Dispersive Infrared (NDIR)

- Reference Standards: EN 15058 (EU), US EPA Method 10

- Measurement Type: CO

- Advantages: Robust, highly selective for CO, suitable for harsh industrial environments.

- Applications: Stack emissions, engine testing, process monitoring.

- Alternative: Gas Filter Correlation (used for some US EPA applications).

Carbon Dioxide (CO₂)

- Standard Method: Non-Dispersive Infrared (NDIR)

- Reference Standards: EN 15058 (same standard as CO), US EPA Method 3A

- Measurement Type: CO₂

- Advantages: Reliable and widely used for combustion analysis.

- Applications: Combustion analysis, flue gas monitoring, CEMS.

- Note: Often measured alongside CO using dual-channel NDIR analysers.

Oxygen (O₂)

- Standard Method: Paramagnetic Detector

- Reference Standards: EN 14789 (EU), US EPA Method 3A

- Measurement Type: O₂

- Advantages: No gas consumption, fast response, accurate over a wide range, highly selective for oxygen.

- Applications: Stationary emissions monitoring, combustion efficiency control.

- Alternative: Zirconia Cell (ZrO₂) (robust, high temperature tolerant, used in boiler control and process applications, but not the primary SRM in Europe).

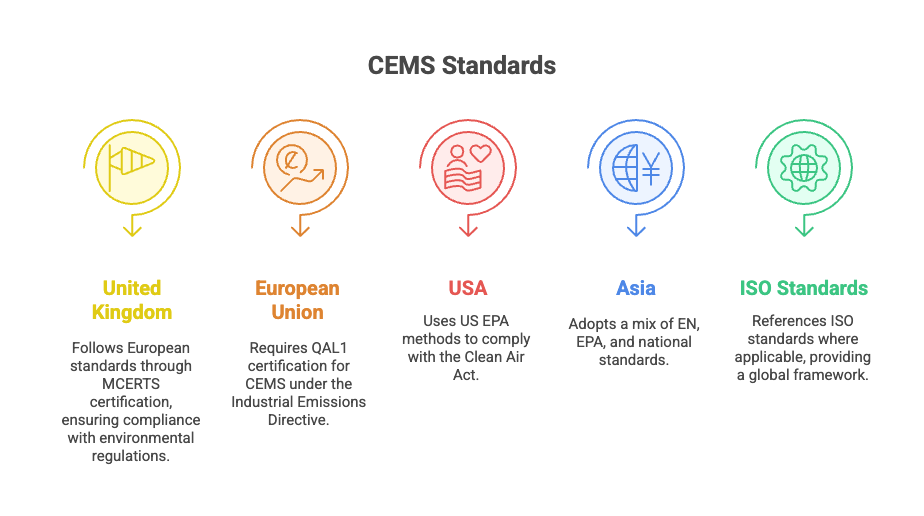

Global Standards Alignment

- United Kingdom: Adheres to European standards (EN methods) via MCERTS certification under the Environment Agency, ensuring compliance with UK environmental regulations.

- European Union: QAL1 certification (EN 14181) is a mandatory requirement for CEMS under the Industrial Emissions Directive (IED), ensuring the quality assurance of automated measuring systems.

- USA: US EPA methods are utilised for compliance with the Clean Air Act and other federal environmental regulations.

- Asia: A blend of EN, EPA, and national standards (e.g., China HJ methods, Korea NIER methods) are adopted, reflecting diverse regulatory landscapes.

- ISO Standards: International Organisation for Standardisation (ISO) standards are widely referenced where applicable (e.g., ISO 12039 for NOx), providing a global framework for quality and comparability.

Signal Group: Engineering Excellence in Reference-Standard Instrumentation

Signal Group, a recognised leader in gas analysis technology, designs and manufactures instruments that consistently meet and often exceed the rigorous demands of reference standard applications. Our commitment to precision engineering and metrological integrity has made our analysers trusted by environmental regulatory bodies, leading research institutions, and industrial compliance teams globally.

SOLAR – Heated Flame Ionisation Detector (FID) VOC Analyser

The SOLAR is a state-of-the-art heated Flame Ionisation Detector (FID) analyser specifically engineered for the precise measurement of Volatile Organic Compounds (VOCs) and total hydrocarbons (THC). Its operational principle relies on the ionisation of carbon-containing compounds in a hydrogen-air flame, generating a current proportional to the carbon concentration. This technique is widely recognised as a primary reference method for VOC analysis due to its high sensitivity and broad applicability.

Key Technical Specifications (S4 SOLAR):

- Measurement Technique: Flame Ionisation Detector (FID)

- Measuring Ranges: User-selectable ranges:

- Range A: 0-1000ppm. Resolution: 0.01ppm.

- Range B: 0-10,000ppm. Resolution: 0.1ppm.

- Range C: 0-100,000 ppm. Resolution: 1ppm.

- Noise: ±0.1 ppm or 1% of range, whichever is greater.

- Response Time: THC <1.5 seconds; CH₄ and NMHC <2.5 seconds.

- Repeatability: <1% FSD (Full Scale Deflection).

- Linearity: ±0.5% FSD or 2% of point.

- Oxygen Effect: <2% of reading from 0% to 21% O₂ (with H₂He fuel).

- Drift: ±0.2 ppm or 2% of range per week, whichever is greater.

- Operating Temperature: Heated version operates up to 200°C for sample conditioning, preventing condensation of high-boiling point VOCs.

- Compliance: MCERTS applied for; EN 12619 compliant.

Applications include combustion studies, continuous emissions monitoring (CEMs), source testing, and industrial emissions analysis where accurate VOC quantification is paramount.

QUASAR – Chemiluminescence NOx Analyser

The QUASAR is a high-performance chemiluminescence (CLD) analyser designed for the precise and simultaneous measurement of nitric oxide (NO), nitrogen dioxide (NO₂), and total oxides of nitrogen (NOx). The chemiluminescence principle, involving the reaction of NO with ozone (O₃) to produce an excited NO₂ molecule that emits light upon relaxation, is the internationally recognised reference method for NOx analysis.

Key Technical Specifications (S4 QUASAR):

- Measurement Technique: Chemiluminescence Detector (CLD).

- Measuring Ranges: User-selectable ranges:

- Range A: 0-1 to 0-1000ppm.

- Range B: 0-10 to 0-10,000ppm.

- Range C: 0-100 to 0-100,000 ppm.

- Zero Noise: <0.1 ppm.

- Span Noise: <±0.1% FSD for vacuum version; <±0.3% FSD for non-vacuum version.

- Response Time: <2.0 seconds.

- Repeatability: <1% FSD.

- Linearity: ±0.5% FSD or 2% of reading.

- Quenching Effect: <2% of reading per 15% CO₂; <2% of reading per 2% H₂O.

- Zero Drift: <0.5% FSD/24 hours.

- Converter Efficiency: NOx >95%; NH₃ >85% (when used with an appropriate converter).

- Compliance: EN 14211 and US EPA Method 7E compliant.

The QUASAR is extensively utilised in engine emissions certification, catalyst validation, and environmental monitoring applications where the accurate speciation and quantification of NOx are critical.

Other Signal Group Reference-Standard Analysers

Signal Group offers a comprehensive portfolio of analysers that align with various SRMs:

- 3010 MiniFID: A compact, portable FID analyser for VOCs, offering similar performance characteristics to the S4 SOLAR in a smaller footprint, ideal for field applications.

- Pulsar NDIR: Utilises Non-Dispersive Infrared technology for precise measurement of CO and CO₂ (and many others), compliant with EN 15058 and US EPA Methods 10 and 3A. Features high selectivity and stability for these critical combustion gases.

- Aurora Paramagnetic O₂ Analyser: Employs the paramagnetic principle for accurate and interference-free oxygen measurement, adhering to EN 14789 and US EPA Method 3A. Essential for combustion efficiency and dilution correction in emissions monitoring.

The Indispensable Role of Reference-Grade Analysers

For professionals engaged in:

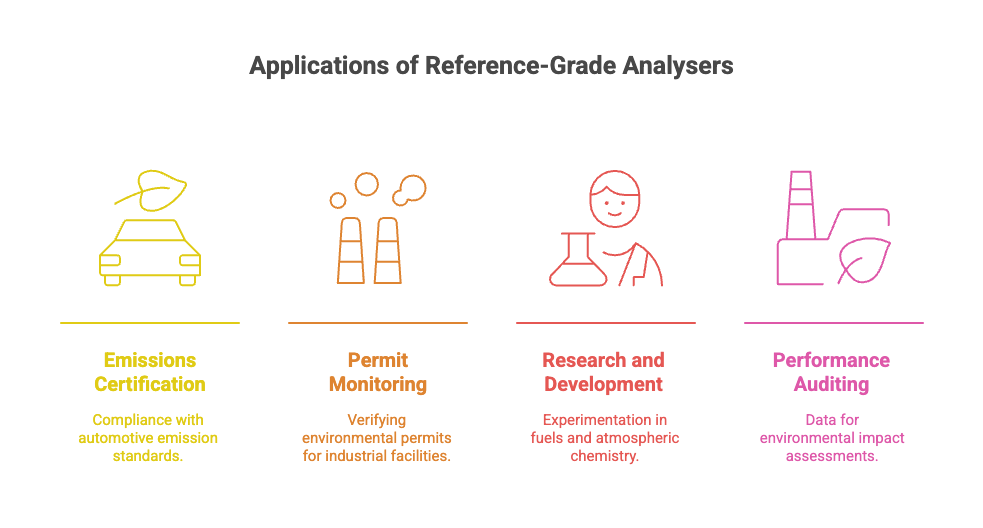

- Vehicle and Engine Emissions Certification: Ensuring compliance with stringent automotive and non-road mobile machinery emissions standards.

- Industrial Permit Monitoring: Verifying adherence to environmental permits for industrial facilities, particularly for VOC and NOx emissions.

- Advanced Research and Development: Facilitating precise experimentation in alternative fuels, catalyst development, and atmospheric chemistry.

- Environmental Performance Auditing: Providing irrefutable data for environmental impact assessments and compliance audits.

Utilising reference-grade analysers from Signal Group ensures that your analytical data is not only accurate and reliable but also stands up to the most rigorous scrutiny from regulatory bodies and scientific peers. This commitment to metrological excellence drives real progress in environmental protection and technological innovation.

Contact Signal Group for Expert Consultation

To specify the optimal reference-standard analyser for your specific application, or to discuss your advanced gas analysis requirements, please contact our technical sales team:

Email: sales@signal-group.com Website: www.signal-group.com