Gas analysers are performing a vital role for packaging manufacturers looking to check the environmental performance of their latest products as they seek new ways to develop sustainable packaging.

Signal Group, the UK based manufacturer of gas analysers, has seen a particular increase in demand for its continuous VOC measurement instruments in the packaging sector. VOCs (volatile organic compounds) are emitted during the manufacture of many packaging production processes, but these harmful pollutants are tightly regulated so continuous monitoring is necessary. In addition, it would not be possible, for example, to label a recyclable product as more sustainable if it caused an increase in VOC emissions.

“The packaging industry is currently under enormous pressure,” explains Signal MD James Clements. “Firstly, most of the major players have made commitments under their ESG policies to improve the sustainability of their products. They are doing this because their customers demand it, consumers want it, and of course it’s the right thing to do, but sustainability means different things to different people,” he says. “Secondly, new regulations such as the UK’s Extended Producer Responsibility (EPR) and the EU’s Packaging and Packaging Waste Regulation (PPWR) are strongly encouraging packaging manufacturers to increase the use of recycled materials and to develop recyclable and reusable products.”

According to a recent McKinsey report: “The global packaging sector continues to be attractive and is expected to grow faster than global GDP. Industry demand for—or at least interest in piloting—sustainable packaging is also rising as a result of pledges by companies across the value chain to reduce material use, increase circularity, and make more use of recycled materials.”

However, as James Clements explains: “It’s not as simple as that. Yes, waste reduction is enormously important, but the development of new packaging products can be a bit like ‘whack-a-mole’ because sustainability objectives also include other important factors such as carbon footprint and environmental emissions.

“Whilst seeking to develop new, more sustainable and recyclable products, packaging companies are also looking to ensure that they do not inadvertently increase their emissions of pollutants such as VOCs, and this where we are seeing a large increase in demand for continuous analysers,” he adds.

VOC sources

VOCs are released by a variety of packaging manufacture processes. Plastics, resins, fibres, textiles, elastomers, solvents, pigments, adhesives and many other products can be manufactured from fossil fuels, chemicals, catalysts and recycled materials, but many of the processes by which these materials are transformed into packaging result in VOC emissions. During polymerisation, for example, unreacted monomers and residual catalysts can be released as VOCs. In addition, the chemicals that are added to the polymers can also be volatile and become VOCs, and during processing at high temperatures, polymers can degrade into smaller, volatile compounds, which are also VOCs.

The manufacture of some food packaging involves the application of a plastic membrane (PET, HDPE, LDPE, PP etc.) to cardboard or paper. This is a good example of a process that releases VOCs which have to be abated. Typically, a Regenerative Thermal Oxidizer (RTO) is used to destroy the VOCs and other industrial pollutants in exhaust gases by oxidizing them into harmless substances like carbon dioxide and water vapour. RTO abatement systems have to be controlled by a gas analyser. For example, a Signal FID can take samples from both ends of the RTO to check abatement performance and demonstrate regulatory performance. This can be achieved with two FIDs or with one FID and a switched sampling system.

Monitoring technology

The standard reference method for the analysis of VOC emissions is by a Flame Ionisation Detector (FID), which for many years has been at the heart of Signal’s VOC analysers. The FID method is specifically designed to detect carbon-hydrogen (C-H) bonds, making it highly selective for VOCs.

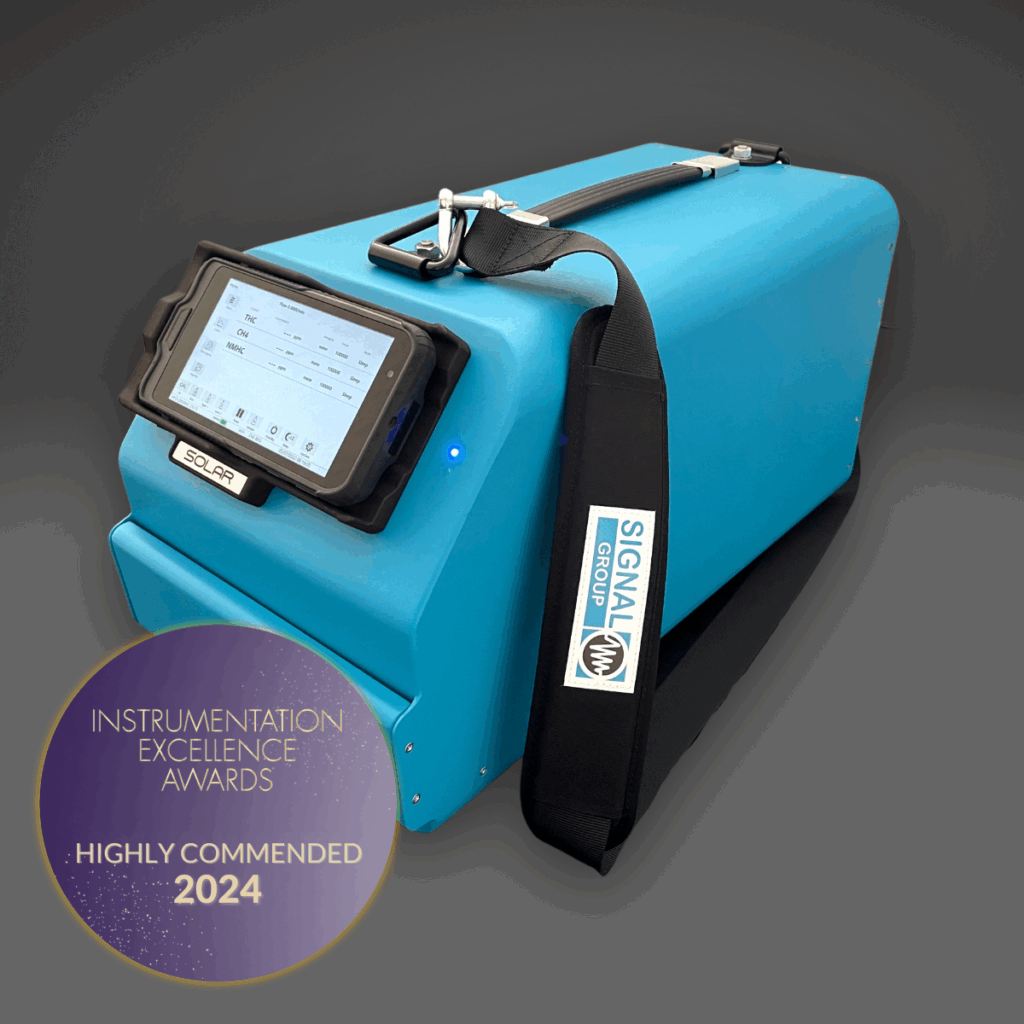

Signal manufactures two main types of FID – fixed and portable. The fixed analysers are permanently deployed to measure VOC emissions in one location, and the portable analysers can be used at multiple sites, where discontinuous monitoring is permissible. These are generally sites with lower emissions where periodic measurements suffice.

In many countries, the monitoring of VOCs for regulatory compliance requires certification to specific performance standards. For example, Signal’s latest FID, the SOLAR CEMNEX, recently passed a rigorous program of tests at TÜV in Germany. As a consequence, this monitor has MCERTS approval verifying that it complies with the performance and uncertainty requirements specified in the UK’s Environment Agency Guidance: MCERTS for stack emissions monitoring equipment at industrial installations – Continuous emissions monitoring systems (CEMS) Updated 28 August 2024, EN 15267-1:2023, EN15267-2:2023, EN 15267-3:2007 and QAL 1 as defined in EN 14181: 2014.

Summary

It is possible to claim that a product is more sustainable if it has a lower carbon footprint, produces less environmentally harmful emissions, uses less energy and/or water, or if it results in less waste. However, if it only achieves one of these admirable goals, it is important to check that it is not doing so at the expense of the others, and that is why packaging manufacturers are using more VOC analysers.