Signal Group is currently celebrating the 30th anniversary of its gas sample cooler/dryers. Over the years, Signal has developed a fleet of ancillary equipment to ensure the accuracy and reliability of its gas analysers, and this has included cooler/dryers that condition sample gas before analysis.

Despite advances in technology, Signal Group has remained true to its guiding principles of simplicity and reliability in product design. “Once we had developed models that met our needs precisely, further development was unnecessary, and we now have hundreds of cooler/dryers operating all over the world,” says Signal’s Managing Director, James Clements.

Stack, flue, or exhaust emission samples are typically conditioned before analysis, and regulations dictate that this conditioning should be compatible with the analysis method. Cooler/dryers remove moisture from the sample gas, preventing it from affecting the readings or harming the analyser. However, cooler/dryers are not typically used with acidic gas samples because acidic gases may dissolve in the condensed water and not form part of the measurement.

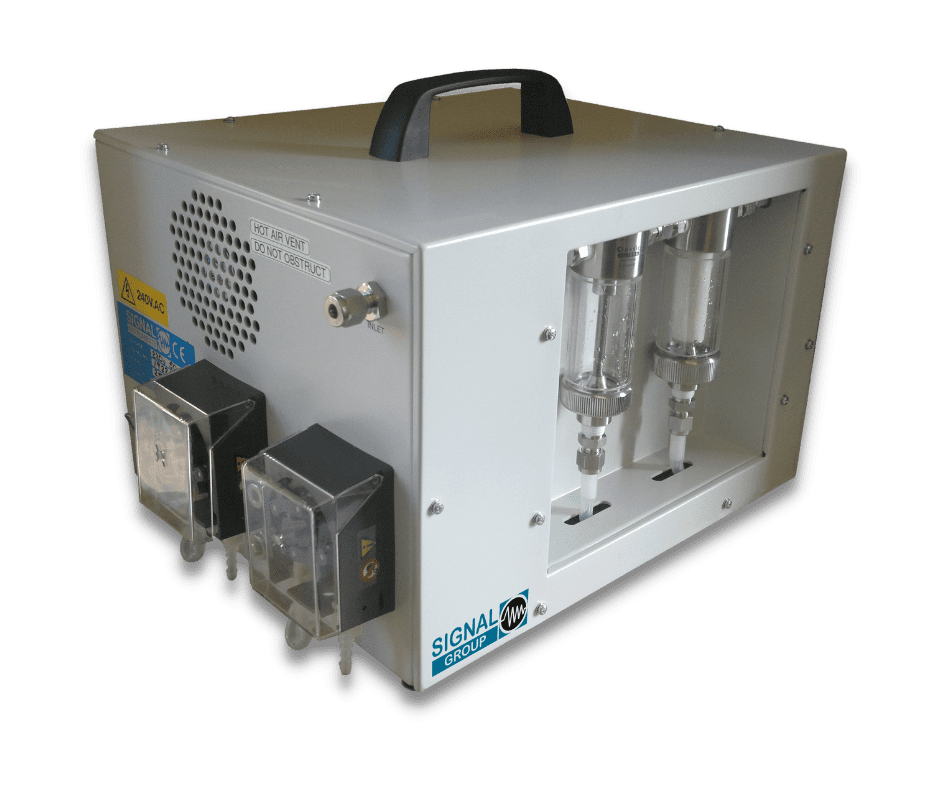

Signal Group offers two types of cooler/dryer with a thermoelectric cooling system and a special gas labyrinth design to eliminate the possibility of losing non-soluble sample gas with the removed water. The portable Model 250 cooler/dryer weighs 15kg and runs on mains power, while the 19” rack version (Model 200SM) is available as a 1, 2, or 3-channel unit.

“It is incredible that there has never really been any need to update or redesign our cooler/dryers, but they do say: if it ain’t broke, don’t fix it!” concludes James Clements.

For more information or to request a quote, visit the 250 Portable product page or the 200sm product page.