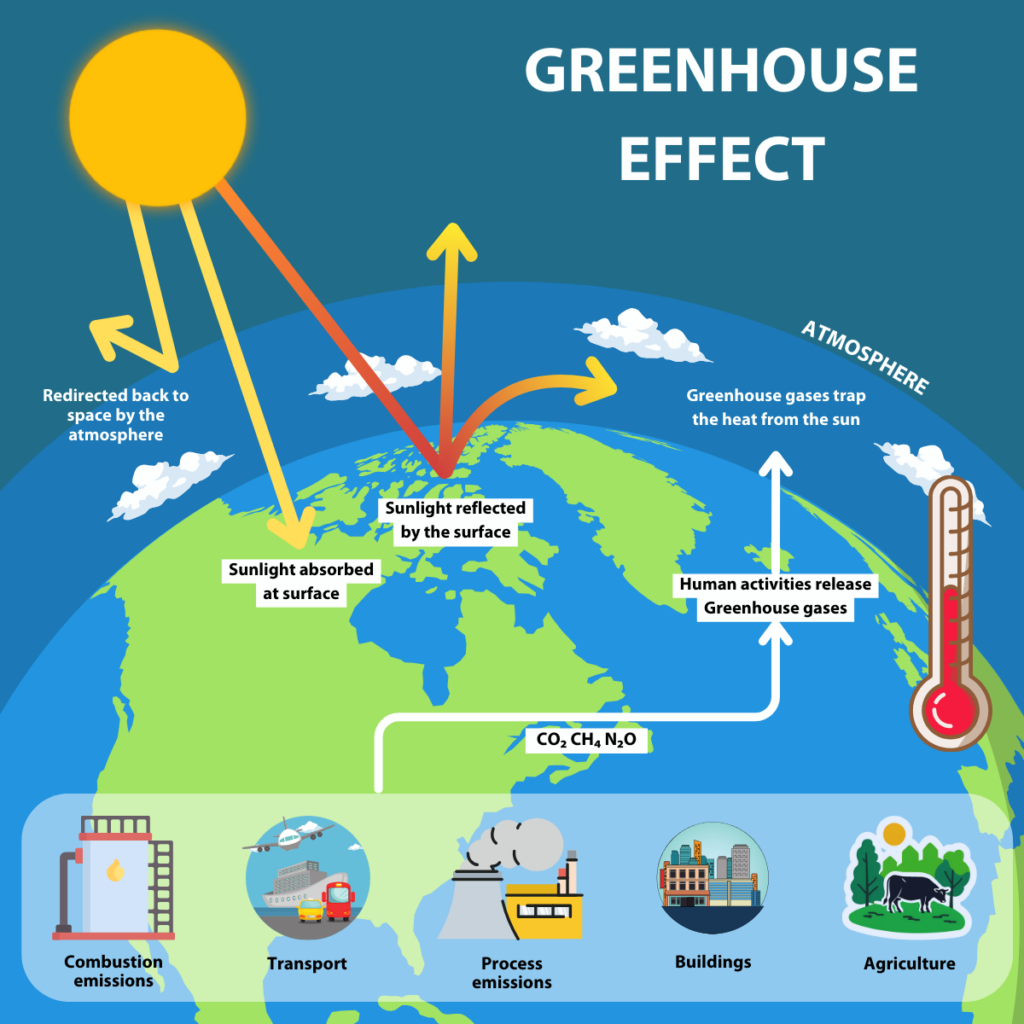

As the world urgently seeks ways to decarbonise, James Clements from Signal Group explains how gas analysis will perform a vital role – not just for CO2 but for all of the important greenhouse gases.

The climate crisis is forcing nations to urgently find ways to lower their greenhouse gas (GHG) emissions, and carbon capture is likely to be one of the key technologies in enabling this goal.

Carbon capture and storage (CCS) involves the capture of CO2 emissions from industrial processes, such as steel and cement production, or from the combustion of fossil fuels to generate power. Primarily, this CO2 is then stored underground in geological formations. Alternatively, it could be utilised in industrial processes by converting it into plastics, concrete or biofuel, for example. This is known as Carbon Capture Utilisation and Storage (CCUS). However, with all of these options, as the saying goes: ‘you can’t manage what you don’t monitor’ so the measurement of GHGs such as carbon dioxide, methane and nitrous oxide will be essential.

It is important to acknowledge that carbon capture may not be the silver bullet that solves the climate crisis. Firstly, it has yet to be implemented on a large scale, secondly, even if it is successful, it will only partially lower GHG emissions, and thirdly many environmental groups are unhappy with reliance on carbon capture because it risks extending the use of fossil fuels. Nevertheless, given the climate emergency, enormous investments in carbon capture are either underway or planned.

According to the Global CCS Institute, in its Global Status Report 2024, over the previous 12 months, the number of CCS facilities in operation globally had risen to 50, while the total number of facilities in the development pipeline has surged 60% to 628. At the same time, the carbon capture capacity of facilities under construction increased by 57%.

The UK is one of the countries leading the growth in carbon capture capacity. In October 2024, for example, the UK government announced £21.7 billion of funding for carbon capture projects over 25 years. The announcement is in line with the UK’s ambition to store 20 to 30 million tons of CO2 per year by 2030 by using CCS technology.

Many other countries are also legislating for and investing in decarbonisation strategies including carbon capture. The EU for example has set a target of 50 Mtpa CO₂ injection capacity by 2030, introduced by the Net-Zero Industry Act, which came into force in June 2024. In the USA the DOE has awarded or is negotiating awards for over US$2.2 billion from the 2021 Bipartisan Infrastructure Law (BIL) to advance carbon management projects. 231 Class VI CO₂ injection well permit applications are being evaluated for 88 projects across 18 US states and one tribal nation under the US EPA’s Underground Injection Control (UIC) program.

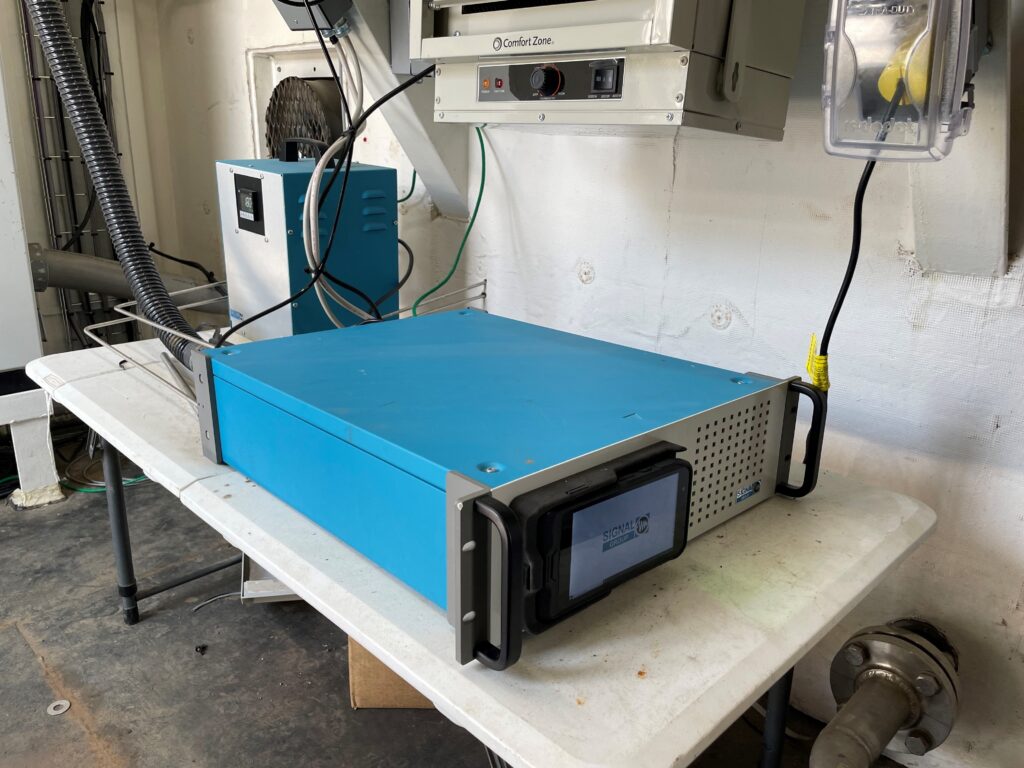

At Signal Group, our main involvement with carbon capture has been with combustion processes involving fossil fuels or waste derived from fossil fuels. To-date these projects have largely been in the pilot stage, as researchers and process operators seek to refine and prove the technology before investing in a full-scale facility. For example, Signal analysers are being utilised at a pilot carbon capture unit at a natural gas combustion plant in southern Arkansas, USA. The company Aqualung Carbon Capture is trialling its novel carbon capture technology on a generic gas-fired boiler, and approached Signal for help with its requirement to continuously check for non-combusted hydrocarbons in the boiler’s emissions.

Explaining the advantages of Aqualung’s membrane technology, Jonathan Garbett said: “Traditional carbon capture techniques such as absorption with amines are relatively expensive, with a requirement for amine, heat and a steady stream, so they are only used commercially in larger applications. In contrast, our patented membrane technology requires less power and works well on smaller, de-centralised plants.”

Signal’s gas analysis system included an S4 SOLAR heated FID VOC analyser with a heated line and model 346 front-end filter. In most countries, FID (flame ionisation detection) is the standard reference method for the measurement of total hydrocarbons, and the sampling handling system is designed to ensure that the sample being delivered to the analyser is truly representative of the emissions, with no possibility of condensation in the sample line, or the analyser.

Choosing a GHG analyser

In the example above a Signal analyser is being used to detect incomplete combustion; not just for safety reasons, but also because fossil fuels are inevitably an important part of the transition to a decarbonised economy, so it is vital that where they are used, they are utilised as efficiently as possible.

In order to be able to check and verify carbon capture it is necessary to measure GHGs both before and after the capture process. Consequently, it is preferable to deploy analysers that are able to take samples from two different locations concurrently, and frequently it will also be necessary to be able to continuously measure more than one GHG.

S4 PULSAR gas analysers employ Gas Filter Correlation technology to measure only the gas, or gases, of interest, with negligible interference from other gases. The optical bench is enclosed in a heated chamber which means that an external chiller is not necessary for non-condensing samples. By using two sample cells of different lengths, in series, it is possible to select a low-range and a high-range. This is important for applications such as carbon capture where high levels exist before capture, and very low levels after. A parallel twin optical bench version is also available for applications requiring the measurement of two different gases or two ranges of the same gas running continuously.

In addition to their remote connectivity software (S4i), Signal’s S4 analysers also feature a rugged, detachable tablet which serves as a control screen, and connects wirelessly to the analyser via an inbuilt 802.11 wifi that can connect up to 50 metres away. This provides users with the enhanced ability to view live data from a different (safer or more convenient) location, and even manage data logging, alarms and calibration.

At the moment, many carbon capture projects are still at the pilot stage, and GHG analysis is performing a vital role within them, helping to evaluate and verify carbon capture techniques. As full-scale projects are implemented, gas analysis will play an even more important role, demonstrating not just that carbon has been captured, but also how much. This function will be critically important in carbon markets.

COP29 moved towards the establishment of a global carbon market

A significant outcome from COP29 in Baku was agreement on the remaining sections of Article 6 of the Paris Agreement, to enable the development of a global carbon market. Article 6 details how participants can pursue voluntary cooperation to reach their climate targets – with the Paris Agreement Crediting Mechanism identifying and encouraging opportunities for verifiable emission reductions.

Following protracted negotiations in Baku, developed nations also agreed to help channel at least $300bn a year into developing countries by 2035 to support their efforts to deal with climate change. This finance will be used for adaptation, mitigation, renewable energy, agriculture, loss and damage, and debt restructuring. Of these measures, mitigation (reducing emissions and enhancing sinks) will help drive the growth in carbon capture.

Here at Signal Group, we very much welcome initiatives to accelerate GHG emissions reductions. Some carbon credit projects do not involve the direct measurement of GHG gases – wind farms and forest conservation for example. However, it is important to note the word ‘verifiable’ in carbon trading texts, and this is where our GHG analysers will play a critically important role, because, where GHGs are emitted, it is only possible to claim GHG emissions reductions (by carbon capture for example) if they are measured, and one of the most important ways to do this is with an accurate, reliable gas analyser. Further measurements will be necessary if the captured carbon is stored or utilised (CCS or CCUS).

Signal’s S4 PULSAR analyser employs NDIR technology to measure a range of critically important gases including GHGs such as carbon dioxide, nitrous oxide and methane. The S4 PULSAR is an extractive gas analyser, capable of drawing samples from both before and after carbon capture, so that effective GHG emissions reduction can be demonstrated.

To generate carbon credits, a project’s emission reductions need to be measured and quantified. This involves calculating how much CO2 (or equivalent GHGs) has been avoided or removed compared to the baseline. The calculation depends on the specifics of the project and involves standard methodologies set by certifying bodies. It is important to note that although the term ‘carbon credits’ is applicable, it is actually a term that applies to all GHGs – hence the mention of ‘or equivalent GHGs’.

With the ability to measure a range of GHGs, the S4 PULSAR uses reference method gas analysis for important gases such as methane and nitrous oxide. Why are they important? Well, methane is about 25 times more powerful as a GHG than carbon dioxide, and nitrous oxide is 300 times more powerful!

Summary

The successful achievement of global net zero targets will depend on an enormous array of factors. However, accurate, reliable, verifiable data will be essential if the data produced by organisations and countries are to be trusted.